May 4, 2025

At Social Nature Movement, composite repairs are not just something we do—they’re what we’ve perfected. From finely crafted outrigger canoes to high-performance gear and marine equipment, we restore strength, structure, and style to damaged composites using world-class materials and methods.

We work hands-on with carbon fibre, Kevlar (aramid), fibreglass, epoxy resin, and hybrid layups—bringing things back to life when others might deem them irreparable. Whether you’ve got a cracked racing canoe, a delaminated hull, or a fatigued component, our workshop in Auckland is where composites get a second chance.

Here’s how we do it—and why our clients trust us to make their gear better than ever.

Composites are incredibly versatile, but also unforgiving when it comes to damage. That’s why understanding the exact behaviour of each material is critical. Our expertise spans the full range of reinforcement fibres and matrix systems, including:

Carbon Fibre – Incredibly light and stiff, but brittle. We restore cracked or fractured carbon with precise layup realignment and matched fibre orientation.

Kevlar – Tough, abrasion-resistant, and used in high-impact applications. We cut, seal, and rebind it with care to avoid fraying and delamination.

Fibreglass – Flexible, forgiving, and cost-effective, fibreglass remains a core material in many kayaks, canoes, boats, and enclosures. We use it for both structural and cosmetic repairs.

Hybrid Layups – Combining multiple fibre types is common in modern builds. We understand the role of each layer and restore accordingly.

Epoxy and Vinyl Ester Resins – Our resin work is critical. We use only marine-grade systems that are matched to the base composite, ensuring optimal bond strength and water resistance.

With every project, we take into account the stresses, loads, and environmental exposure your gear faces, and tailor the repair approach to suit.

From the surface to the core, damage in composite materials can take many forms—some obvious, others hidden. We’ve repaired it all:

Delaminated panels where the layers have started to peel or separate

Crushed cores from impacts or excessive weight

Fibre ruptures in carbon or aramid cloths

Stress cracks or spidering in resins from flex or UV exposure

Water ingress and osmosis in older boats or improperly sealed parts

Our first step is always damage diagnosis. Sometimes a tap test will reveal hollow-sounding voids. Other times, we’ll sand back gelcoat or top layers to discover the true extent of fibre or core damage.

We treat each job as unique—there’s no one-size-fits-all patching here. We rebuild from the inside out, restoring original shape, strength, and function.

We believe a proper repair should not only look good—it should hold up under pressure. Here’s how we bring gear back to life:

We start with a full inspection to map out the damage. Whether it’s visual, tactile, or even thermal, we want to understand what’s failed—and why—before we start cutting.

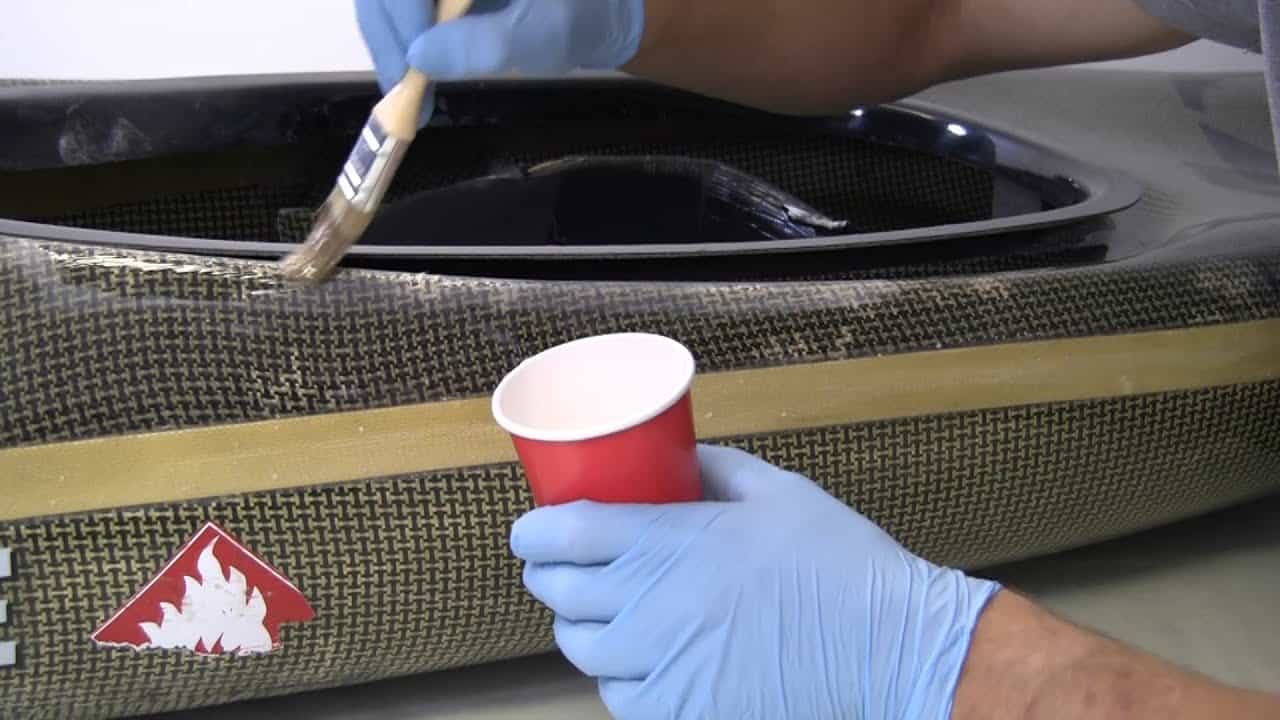

Preparation is everything in composite repair. We carefully sand or grind a tapered area around the damage site to allow a strong mechanical and chemical bond. This scarf joint method ensures seamless transition from the original laminate to the new one.

We select the appropriate cloth—carbon, Kevlar, glass, or hybrid—and cut it into layers that rebuild the original strength profile. Using high-quality marine resins, we wet out the fibres, remove air bubbles, and carefully position the cloth with perfect fibre orientation. For structural jobs, we often use vacuum bagging for tight compaction and resin control.

Our repairs are cured either at ambient temperature or, when needed, with controlled heating to improve resin performance. Epoxy post-curing increases the glass transition temperature, meaning your part can handle higher heat and load before softening.

Once cured, we sand and fair the area to blend with the original profile. If required, we paint, clear-coat, or gelcoat the repair—so not only does it perform, it looks just like new (or better).

Though much of our repair work focuses on marine and paddlecraft, we also apply our composite knowledge to:

Outdoor adventure gear – Paddles, helmets, poles, foils, and more

Cycling components – Carbon frames, seat posts, forks

Watercraft & boards – Kayaks, surfboards, SUPs, canoes, amas

General recreation equipment – Shelters, sleds, safety enclosures

If it’s made from carbon fibre, Kevlar, or glass—and it’s broken—chances are we can fix it. We’ve salvaged gear from land, sea, and sky.

We believe that repairing is better than replacing—both for your budget and the environment. Composites are expensive to produce and energy-intensive to manufacture. By restoring existing gear, we help:

Reduce waste and landfill

Lower carbon emissions

Extend product life cycles

Save clients the cost of full replacement

We also reuse and recycle composite offcuts in training projects and workshops, reducing material waste further.

At Social Nature Movement, we bring the technical mindset of a composite engineer and the hands-on craftsmanship of a canoe builder. We’re not just fabricators—we’re users. We paddle, ride, and adventure in the same environments our clients do. We understand how gear gets used, how it fails, and how it should feel when it’s repaired properly.

Clients trust us because:

We communicate clearly

We match materials intelligently

We repair like we’re rebuilding it for ourselves

We respect the cultural and practical value of every item

Composite repair isn’t just a trade—it’s a form of stewardship. When you bring us something broken, we don’t just slap on a patch. We strip it back, study it, and rebuild it to last. That’s our promise.

Whether it’s a carbon hull, a cracked ama, a delaminating paddleboard, or a Kevlar racing canoe, we’ll return it to you stronger, stiffer, and more resilient.

At Social Nature Movement, composite restoration is in our fibre.

email support@snm.nz or call us on 0800 76 62 66